High quality fusing machine for clothing, outerwear, shirts and leather.

The machine is available with a belt width of 600-750-1000 mm.

It has a working area of 1000 mm long, which allows several operators to load the pieces to be thermoadhesive. Such area consists of a work surface and a belt section that easily receives the pieces to be loaded into the machine. The transport system consists of a lower belt and an upper belt, made of fiberglass with antistatic treatment, Teflon coated and without join. Compensating rollers guide the belt, excluding the formation of folds and corrugations.

The 920 mm long heating surface is made up of a series of 7 laminated profiles that form curved panels.

The pressing system can be single or double.

The scraper bars in Teflon graphite allow the total detachment of the outgoing pieces, finally the cooling station ensures that the pieces may be unloaded by hand or automatically cool down in such a way as not to leave marks.

The machine is equipped with continuous upper and lower cleaning.

Key Advantages

- High performance press for high quality, high volume continuous fusing.

- Two independently regulated heating zones.

- Specially insulated heating elements for minimal energy loss.

- Rapid, precise and stable temperature controls.

- High quality materials, industrial grade construction for low maintenance & high reliability.

- Teflon blade and coated aluminium bar to ensure that both upper and lower belts are maintained constantly clean.

- 7” Touch Screen System with programs.

- Heating control with impulse static relays.

- Insulation for energy saving.

- High temperature bearings, maintenance free.

- Seamless belts.

- Entirely engineered and manufactured in Italy.

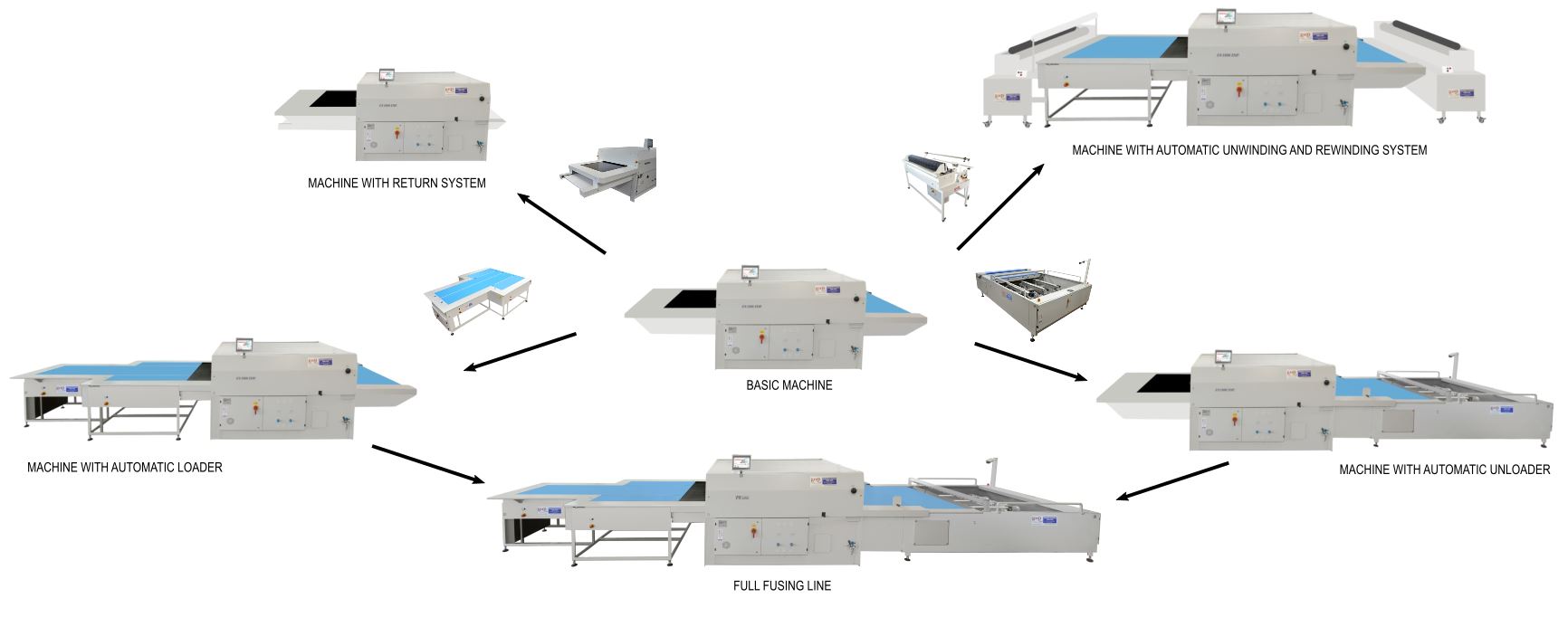

HOW TO ACCESSORIES THE MACHINE: